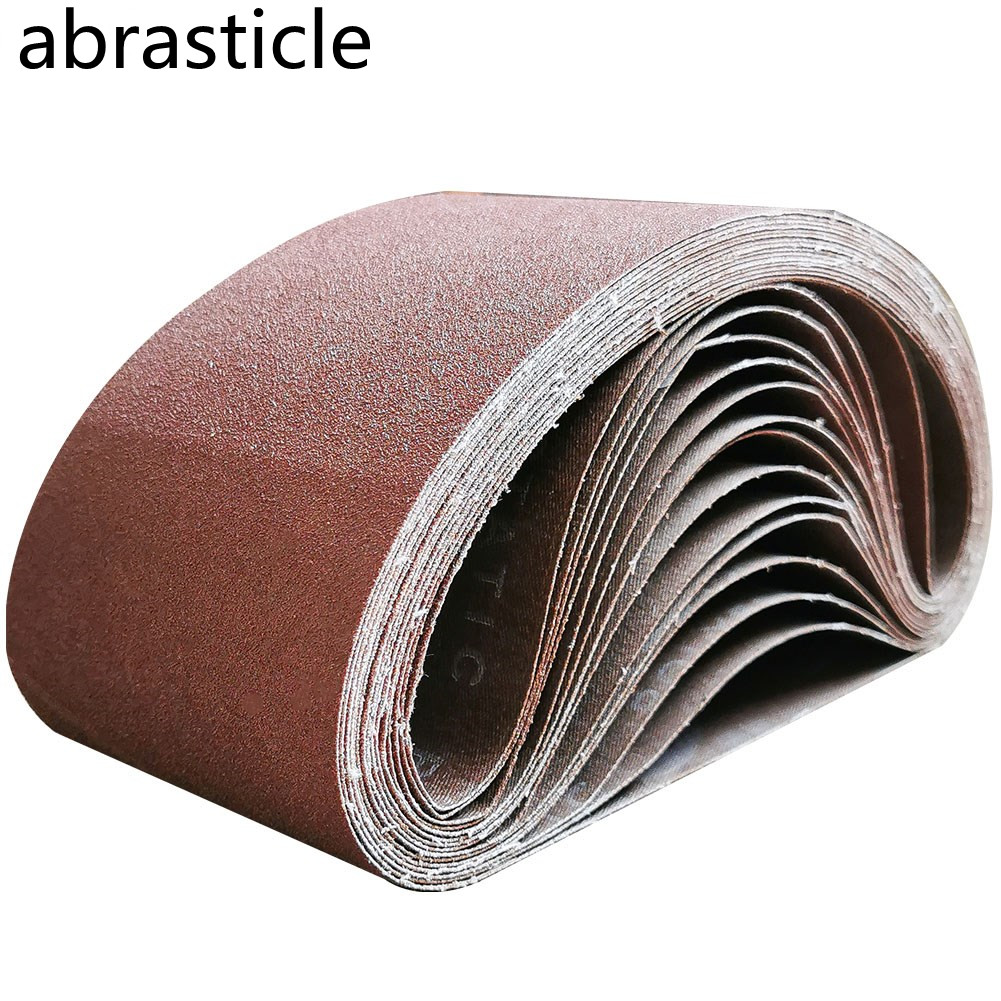

abrasticle abrasive belt

abrasticle abrasive belt

0 Reviews

$

13.50

$13.50

-0%

Qty:

In stock

30-day Return Policy,

Learn More

Description

Product Detail

customers reviews ( 0 )

0

/ 5.0

5 stars

0%

4 stars

0%

3 stars

0%

2 stars

0%

1 stars

0%